Eco-efficient operations

Performance

Performance Manufactured capital

Manufactured capital Natural capital

Natural capital

Alignment to the SGDs

![]()

Insuring the efficient use of natural resources is one of the drivers in the Ultra Group’s management model. The model seeks not only to comply with the legislation, but also to continually develop practices that reduce the Group’s impacts on the environment to a minimum.

In addition to its commitments to social and environmental responsibility, the Group aims to ensure that its operations are increasingly eco-efficient. This contributes to reducing costs, driving innovation and maintaining its good reputation with consumers, the media, investors and society in general. As a result of the increasing numbers of companies that require suppliers to comply with social and environmental criteria, the Group’s management model, which focuses on eco-efficiency, also strategically positions its businesses that operate, exclusively or partially, in B2B markets.

The Ultra Group’s environmental impacts occur mainly in the businesses, which have their own specific policies and management systems that centralize the processes for prevention, mitigation and management of impacts, and which are based on international standards. A number of the operating units have been certified under ISO 14001 for environmental management, as follows: Ultragaz’s storage base in Capuava/Mauá (SP); all of Ultracargo’s terminals (except for the recently opened terminal in the State of Pará, which is in the process of obtaining certification); the Oxiteno plants in Brazil and Mexico, and Ipiranga’s pool in Betim (MG).

Based on the discussions in the eco-efficiency work-group meetings in 2021, three priority areas for action were identified: energy efficiency, reduction of waste and leakages.

Environmental Performance

Energy

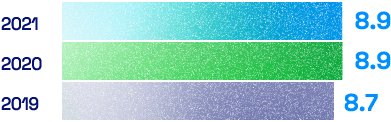

In 2021, the Group’s total energy consumption was 8.9 million GJ, an increase of 1% compared to 2020. The consumption in the Holding reduced by 15.2%. In the case of the consumption in the businesses, there were reductions of 17.5% in Ultracargo and 5.2% in Extrafarma and increases of 2.5% in Ultragaz, 1% in Oxiteno and 16% in Ipiranga.

Ultragaz recorded an increase in fuel consumption of around 8% during the year, due mainly to the expansion of its company-owned vehicle fleet. On the other hand, its electricity consumption decreased by 11% due to the positive impact of internal awareness campaigns. The reduction in fuel consumption in Ultracargo was due to a combination of the lower volume of fuels handled in the Santos terminal and a technical fault with one of the VOC burners in the same terminal in the last quarter, as highlightedin the section on Emission Performance  .

.

In Oxiteno, the higher energy consumption was due to the increased use of fuel to generate steam in the boilers. In Ipiranga, the increased consumption was due to the reactivation of an oil-fed boiler in the pool in Paulínia (SP) in 2021, which had been shut down during 2020. In Extrafarma, fuel consumption decreased by 27.6%, as a result of a project to optimize the delivery routes of the company-owned vehicle fleet. Also, the company outsourced some of its distribution routes in the State of Maranhão.

Total energy consumption (GJ)

| Business | 2019 | 2020 | 2021 |

| Holding | 23,406 | 17,288 | 14,665 |

| Ultragaz | 308,673 | 312,767 | 320,528 |

| Ultracargo | 70,411 | 80,075 | 66,038 |

| Oxiteno | 8,043,089 | 8,231,012 | 8,311,231 |

| Ipiranga | 116,814 | 92,909 | 107,797 |

| Extrafarma | 116,300 | 127,301 | 120,658 |

| Ultra Group | 8,678,694 | 8,861,352 | 8,940,918 |

-

GROUP AMBITION

Ensure a level of excellence in the environmental management of operations, reducing the consumption of energy, water and waste generation.

-

100% of electricity from certified renewable sources

-

Zero waste to landfill

-

Zero leaks with a loss at secondary containment

Water

The Holding and the businesses are in line with the relevant legislation regarding the use of water. They monitor consumption and discharge and adopt measures to minimize impacts. In 2021, the Ultra Group consumed 5.8 million m³ of water, a reduction of 3% compared to the previous year. All the water withdrawn is fresh water. Of the total volume of water withdrawn by the Group in 2021, more than 90% was consumed in Oxiteno due to the nature of its operations. In addition to being a raw material for some products, water is used in the company’s production processes, mainly in heating and cooling systems and steam generation. The company has set a target for 2030 to reduce its global water consumption by 10% and increase the volume of reuse water. Today, for example, at the Mauá unit (SP), 96% of its water withdrawal is reuse water. The units treat effluents and discharge them into water bodies in accordance with the standards required by law.

The water consumption of the Holding, is low and decreased by 17% during the year compared to 2020. It’s consumption is predominantly for domestic use but it also reuses water in its cooling tower. Of the total water represented by the Holding during the year, 14.4% was reuse water. In Ultragaz, the activities of washing bottles and painting cabins represented the majority of its water consumption. To minimize the withdrawal of fresh water, the company adopted a closed-circuit system to recirculate water. The company estimated that 90% of the water used in this process is recirculated. The bottling bases have effluent treatment plants. The water that cannot be reused is removed by certified companies for final discharge. Ultragaz reduced its water consumption by 14% compared to 2020 through a combination of awareness campaigns, improvements to the leakage prevention systems and the pro-active search for improvements by a work-group established to study the theme.

Ultracargo uses reuse water at its terminals in Santos (SP), Itaquí (MA) and Vila do Conde (PA). Furthermore, it reuses water in hydrostatic testing which, in 2021 alone, generated a reduction in water consumption of 36 thousand m³ in the Phase III expansion of the Itaquí terminal and 97 thousand m³ in the construction of the Vila do Conde terminal. ![]()

In Extrafarma, the water consumption, which is primarily for domestic use, was 30% lower compared to the previous year. In Ipiranga, where water is used mainly in the administrative areas and in the operating units’ fire-fighting systems, the consumption was similar to 2020.

Water Withdrawal1 (m3)

| Business | 2019 | 2020 | 2021 |

| Holding | 25,307 | 10,192 | 8,412 |

| Ultragaz | 123,417 | 134,426 | 115,357 |

| Ultracargo | 98,833 | 63,723 | 98,350 |

| Oxiteno | 5,290,975 | 5,677,101 | 5,474,818 |

| Ipiranga | 121,367 | 113,736 | 113,506 |

| Extrafarma | 74,682 | 57,162 | 40,053 |

| Grupo Ultra | 5,734,581 | 6,056,340 | 5,850,495 |

1. The historical series for Ultracargo and the Ultra Group published in the 2020 Integrated Report have been restated.

Water discharge (m3)

| Business | 2019 | 2020 | 2021 |

| Holding | 22,664 | 8,618 | 7,070 |

| Ultragaz1 | 55,701 | 0 | 0 |

| Ultracargo1 | 24,127 | 0 | 0 |

| Oxiteno | 2,160,790 | 2,323,011 | 2,290,942 |

| Ipiranga | 83,324 | 75,561 | 70,236 |

| Extrafarma | ND | 25,516 | 31,464 |

| Grupo Ultra | ND | 2,425,492 | 2,399,712 |

ND: Information not determined/monitored.

1. The effluents generated by Ultragaz and Ultracargo that are transported with a Waste Transport Manifest (MTR) for external treatment in an Effluent Treatment Station, started to be monitored and included in the waste indicators (GRI 306). As a result, there was a reduction of 83% in the consolidated Group’s total volume of water discharged in 2021.

Waste

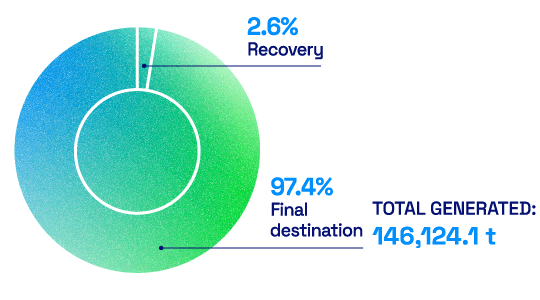

Of the total waste generated by the Holding and the businesses, 2.6% was recycled or recovered. Considering only hazardous waste, 1.1% was sent for recycling or recovery. ![]()

Ultragaz has a policy of not sending hazardous waste (class I) to landfill, even if it authorized to do so by the official waste control body. The only exception to this policy is asbestos waste, which is sent to landfill, in line with the relevant legislation. All suppliers that carry out waste management for the company are evaluated under a specific approval process. ![]()

Ultracargo also has a specific approval process for suppliers who manage the waste generated in their operations. As part of the constant search for the continuous improvement of its environmental management, in 2021, the company improved the accounting of non-hazardous waste and increased the amount of such waste destined for recycling at its Santos (SP) terminal.

Oxiteno has set targets to reduce the generation of waste per ton produced by 10% by 2030 and achieve zero landfill for industrial waste. The waste management process applies to all units, with monthly monitoring of the waste generation and destination indicators. The company actively promotes the recycling and co-processing (for energy recovery) of waste. When this is not possible, waste is incinerated or, as a last resort, sent to certified industrial landfills. Currently, the company only sends waste to industrial landfills in Uruguay, where the options for disposal are restricted, and in Pasadena, United States.

In Ipiranga, the impacts from waste generation occur in the company’s own activities and in its service stations, due to the storage and distribution of fuels. To manage these impacts, the company has a set of internal procedures and it carries out regular inspections and maintenance at the service stations in its network. The waste management procedures include actions to prevent leaks. They are designed to ensure the integrity of the leak barrier and protection systems. The company also monitors atypical situations and process accidents. The company’s headquarters in Rio de Janeiro (RJ) has a center for sorting waste and it sends recyclable materials to waste-picker cooperatives that have now been partners for six years.

Waste Management1

| Holding | Ultragaz2 | Ultracargo2 | Oxiteno | Ipiranga | Extrafarma | Grupo Ultra | ||||||||

| 2020 | 2021 | 2020 | 2021 | 2020 | 2021 | 20203 | 2021 | 2020 | 2021 | 2020 | 2021 | 2020 | 2021 | |

| Generation | 109.1 | 72.9 | 1,195.4 | 1,736.3 | 26,370.8 | 26,166.6 | 14,533.9 | 18,140.8 | 2,835.6 | 3,045.2 | 621.0 | 631.8 | 45,665.8 | 49,793.6 |

| Hazardous | 0.2 | 0.0 | 434.8 | 649.1 | 23,934.9 | 23,451.1 | 7,101.6 | 5,918.4 | 1,778.6 | 1,298.8 | 165.0 | 115.0 | 33,415.1 | 31,432.4 |

| Non-hazardous | 108.9 | 72.9 | 760.6 | 1,087.2 | 2,435.9 | 2,715.5 | 7,432.3 | 12,222.4 | 1,057.0 | 1,746.4 | 456.0 | 516.8 | 12,250.7 | 18,361.2 |

| Recovery4 | 19.9 | 10.1 | 374.6 | 287.4 | 787.2 | 482.7 | 2,530.1 | 2,396.1 | 387.1 | 246.7 | 430.0 | 505.8 | 4,528.9 | 3,928.8 |

| Hazardous | 0.0 | 0.0 | 96.2 | 71.8 | 777.5 | 281.4 | 792,3 | 823,8 | 39.3 | 35.5 | 0.0 | 0.0 | 1,705.3 | 1,212.5 |

| Non-hazardous | 19.9 | 10.1 | 278.4 | 215.6 | 9.7 | 201.3 | 1,737.8 | 1,572.3 | 347.8 | 211.2 | 430.0 | 505.8 | 2,823.6 | 2,716.3 |

| Final disposal5 | 89.3 | 62.8 | 820.9 | 1,448.9 | 25,583.6 | 25,683.9 | 12,288.3 | 16,028.7 | 2,448.5 | 2,794.9 | 183.0 | 126.0 | 41,413.6 | 46,145.2 |

| Hazardous | 0.2 | 0.01 | 338.7 | 577.3 | 23,157.4 | 23,169.7 | 6,578.1 | 5,376.8 | 1,739.3 | 1,275.3 | 165.0 | 115.0 | 31,978.7 | 30,514.1 |

| Non-hazardous | 89.1 | 62.8 | 482.2 | 871.6 | 2,426.2 | 2,514.2 | 5,710.2 | 10,651.9 | 709.2 | 1,519.6 | 18.0 | 11.0 | 9,434.9 | 15,631.1 |

>> drag to the right >>

1. All waste treatment is carried out outside the Group’s premises.

Main types of waste (hazardous | non-hazardous):

Holding: organic material, household waste, rubble, recyclables (paper, plastic, cardboard, metal) | ambulatory waste;

Ultragaz: organic waste, recyclables, effluent treatment plant (ETP) sludge, uncontaminated land | paint sludge, batteries, contaminated personal protective equipment (PPE), contaminated soil;

Ultracargo: sweepings, household waste, recyclables | solvents, oils, contaminated rags and PPE, lamp bulbs, batteries;

Oxiteno: recyclables, rubble, effluent treatment plant (ETP) sludge | obsolete or non-conforming raw materials and products, contaminated packaging;

Ipiranga: garden organic waste, sweepings, organic material, recyclables | used oil, residues from cleaning tanks and water and oil separator boxes, residues contaminated with hydrocarbons;

Extrafarma: recyclables, food, diapers | medicines, sharps, infectious waste.

2. The data for the indicator for 2020 differs from that published in the Ultra Group Integrated Report 2020 because of a change in the regulatory reporting of effluents classified as waste and subject to specific transport and treatment. These amounts have now been incorporated into the indicator.

3. The data was restated after the publication of Ultra Group’s Integrated Report 2020.

4. Recycling, recovery or reuse.

5. Incineration, co-processing and final disposal in a sanitary landfill.

-

Water Security

For the second consecutive year, the Ultra Group responded to the section on water security within the scope of the CDP questionnaire called Disclosure.Insight.Action. The Group received a B score, attesting to the effectiveness of its water resource management.

For more information,

see the CDP website.

Eco-efficiency Initiatives

The Holding and the businesses have carried out a number of projects aimed at increasing eco-efficiency. Some examples are as follows.

Zero Waste to Landfill

Ultragaz has already made progress towards achieving zero waste to landfill. The Mauá (SP) unit was the first unit to commit to the goal and, in July 2021, it was awarded the Zero Landfill Seal, by the company Multilixo.

The initiative avoided approximately 79 tons of waste from being sent to landfills and reduced the costs of waste treatment at the unit by 20%.

Rain Water Catchment

Ultracargo’s terminal in Santos (SP) has a rainwater catchment system. After being treated, the water is used for the hydrostatic testing of tanks and in the cleaning of common areas, among other uses. In 2021, around 30 thousand m³ of rainwater were reused.

The technology has also been applied in the new terminal in Vila do Conde (PA) and in the recently expanded area of the terminal in Itaqui (MA).

Oxiteno has also adopted this practice. In 2021, 35 thousand m³ of rainwater were collected at the Oleoquímica unit, in Camaçari (BA), and 659 m³ in Coatzacoalcos (Mexico)

In Ultragaz, the design of the new base in Miramar (PA) included a rainwater catchment system.

Renewable Energy

Ultragaz, Ultracargo and Ipiranga acquired renewable energy certificates (I-RECs) to offset the GHG emissions from their consumption of purchased electricity in 2021, positively impacting the Group’s performance in Scope 2 emissions.

The Holding, acquired I-RECs in 2022 and they will be used to offset GHG emissions linked to the purchase of energy in 2021.

Solar Energy Plant

In 2021, Ipiranga expanded its Solar Energy Plant project – more than 14 plants are now under construction. They are expected to generate a total of more than 40 MW h/year and will supply more than 530 service stations and franchises in the network, generating a reduction of 11 thousand tons of CO2e and annual cost savings of R$ 5 million.

The first plants had been scheduled to go into operation in 2021, but the completion of the project was postponed to 2022.

Extrafarma already owns five solar energy plants in Marabá (PA) and Cedro (CE). The energy produced is used by its network of local distributors, generating credits for the company in its future energy bills. The installed capacity is sufficient to supply 116 stores in the State of Pará and 89 stores in the State of Ceará.

ESG Dashboard

Energy consumption – Ultra Group Ultra (Millions GJ)

Energy intensity of the Businesses 2021

| Business | Energy intensity 2021 | Variation 2021 vs. 2020 |

| Ultragaz | 0.19 GJ/t of LPG produced | + 6% |

| Ultracargo | 0.0103 GJ/t of product handled | + 26% |

| Oxiteno | 6.18 GJ/t of product manufactured | + 6.5% |

| Ipiranga | 0.0060 GJ/t of product sold | + 11% |

| Extrafarma | 0.0493 GJ/sales (R$ thousand) |

no variation |

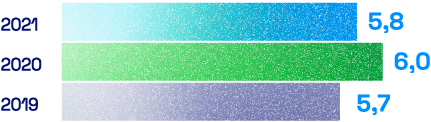

Water Consumption – Ultra Group (millions of m3)

Waste Disposal 2021 – Ultra Group